How to Calculate Cost of Goods Manufactured COGM

The difference between the cost of goods manufactured and the cost of goods sold (COGS) lies in their timing and purpose in the production and sales process. Understanding the difference between net sales and cost of goods sold will enable your company to reduce costs and enhance profits. There was this one company that started using automated machines to do the work of three people. Another business switched to a cloud-based system to manage their inventory and saw a 20% drop in waste. These stories show that with the right moves, you can seriously improve your bottom line. The leftover $20,000 worth of tables is still sitting in your inventory, waiting to be sold.

Cost of goods manufactured vs cost of goods sold

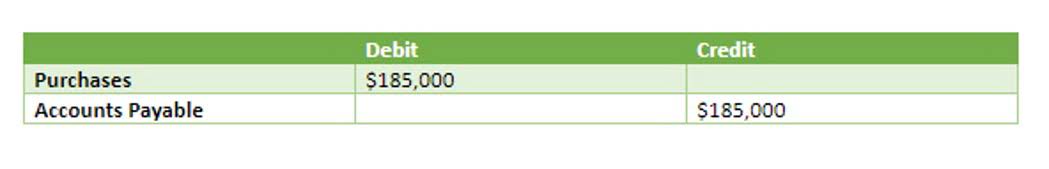

To calculate COGM, add the beginning work in progress (WIP) inventory to the total manufacturing costs, then subtract the ending WIP inventory. Here, you’ll include everything from the obvious expenses, like raw materials, to the less obvious ones, like the cost of running the factory where your products are made. Another closely related KPI crucial in manufacturing accounting is the cost of goods sold or COGS. Whereas COGM depicts the costs of producing all finished goods, COGS only takes into account the costs of producing goods that were sold within the same accounting period. This is important from an accounting point of view as it pinpoints the expense that a company needs to recover per sold product in order to break even. Joint costs are the costs of both raw materials and conversion that cannot be separated.

Manufacturing Overheads Calculation

Let us look at an example of the COGM calculation for a furniture manufacturer. The company has $5,000 worth of furniture in the making at the start of the fiscal quarter. Our writing and editorial staff are a team of experts holding advanced financial designations and have written for most major financial media publications. Our work has been directly cited by organizations including Entrepreneur, Business Insider, Investopedia, Forbes, CNBC, and many others. We follow strict ethical journalism practices, which includes presenting unbiased cost of goods manufactured information and citing reliable, attributed resources. For information pertaining to the registration status of 11 Financial, please contact the state securities regulators for those states in which 11 Financial maintains a registration filing.

What is an example of a COGM?

By analyzing each step, companies can identify inefficiencies and optimize financial performance. Calculate COGM by adding the costs of direct materials, direct labor, and manufacturing overhead incurred during production. This measure provides valuable information for cost management and decision-making, as it helps companies determine the cost of producing a good and its profitability. The journey of manufacturing costs begins with raw materials, the foundational elements transformed into finished products. These materials, such as metals, plastics, and textiles, are procured from suppliers and represent the initial investment in the production process. The cost of raw materials includes the purchase price, transportation, handling, and any import duties or tariffs, which can vary under systems like the Harmonized Tariff Schedule of the United States.

Using cloud manufacturing software for COGM calculation and tracking

The beginning WIP is what’s left unfinished from the previous period, while the ending WIP is what’s still in progress after finished goods are accounted for. Most manufacturers aim to keep ending WIP low–it frees up cash, cuts taxes, and makes accounting a whole lot easier. COGS zooms in on what it costs to produce the goods you’ve actually sold during the period.

Assuming ClockCo has no clocks in production yet, the company only has raw materials inventory. However, as the company moves gears into the production line and starts painting, raw materials inventory is reduced, and a new category of inventory called Work in Process arises. In summary, COGS includes only the direct costs related to the production and sale of goods and excludes other expenses that aren’t directly related to the production process. Get automatic manufacturing cost calculations with Katana, including live inventory management, real-time production planning, and more essential manufacturing features.

- These stories show that with the right moves, you can seriously improve your bottom line.

- John Manufacturing Company, a manufacturer of soda bottles, had the following inventory balances at the beginning and end of 2018.

- Our work has been directly cited by organizations including Entrepreneur, Business Insider, Investopedia, Forbes, CNBC, and many others.

- Calculate COGM by adding the costs of direct materials, direct labor, and manufacturing overhead incurred during production.

- Once all relevant data is captured and allocated, the software automatically calculates the total cost of goods manufactured for each production order or batch by applying the COGM formula.

- For instance, if ABC Manufacturers produced 5,000 products last month but only finished 1,500 of them, their starting WIP inventory for the following month would be 1,500 products.

The cost of goods manufactured (COGM) refers to all the costs involved in producing a product, including direct labor, indirect labor, raw materials, and overhead costs. Total manufacturing cost (TMC), also called total cost of production, is the all-in number for what it takes to make goods during a specific period. It covers everything tied to production–raw materials, labor, and factory overhead.

According to the accrual accounting matching principle, costs are recorded in the period in which the corresponding revenue was provided (and „earned”); for example, $0 in sales results in $0 in COGS. COGM, as opposed to COGS, is attributed to units in production and includes WIP and finished goods that have not yet been sold. Contrarily, COGS is only acknowledged when the relevant unearned revenue inventory is actually sold to a customer. It is important to take into account both the starting and end balances, much like with raw material and work in process inventories.

COGM vs. TMC

Every business has fundamental elements that need to be calculated to determine the total cost incurred in the production process. Every entrepreneur, especially those new to the world of business, often hears the term “Cost of Goods Manufactured” (COGM). While it might sound simple, COGM actually plays a very important role in running a business. Without accurate calculation of production costs, a business may end up setting the wrong selling price, which could negatively affect profits. Airbnb Accounting and Bookkeeping The main components of COGM are direct materials, direct labor, and manufacturing overhead.

Leave a comment